Advance Journal of Food Science and Technology

Exopolysaccharide Production by Streptococcus thermophilus on the Physicochemical Characteristics of Prato Type Cheeses

Advance Journal of Food Science and Technology 2019 17: 7-12

Cite This ArticleAbstract

The aim of this study was to evaluate the effect on the physicochemical characteristics of Prato type cheeses with the production of Exopolysaccharides (EPS) by Streptococcus thermophilus and to compare the results obtained with traditionally-manufactured cheese. There are few studies related to exopolysaccharides produced from lactic acid, however, many investigations describe this production as important in improving the physicochemical characteristics in concentrated milk derivatives like yogurt. In the present study, Prato type cheese was elaborated from three formulations: Traditional (T) (adding mesophilic and thermophilic crop), lyophilized (L) (addition of thermophilic crop) and replicate (R) (addition of thermophilic crop replicated). The physicochemical properties determined were fat, moisture, salt, dry matter, total protein, soluble nitrogen at pH 4.6 and nitrogen 12%; the evaluation was performed at 5, 25, 45 and 65 days of ripening, determining that the bonds formed between the exopolysaccharides, milk proteins and bacterial cells influenced in enhancement of these properties while using the treatments L and R. The results were interpreted by analysis of variance and, depending on the significance, Tukey's test was used with a 5% probability level.

Keywords:

Introduction

Prato is a cheese of Danish origin with characteristics like the Dutch Gouda cheese and Danish Danbo; it has its own characteristics of taste and texture, caused by the adaptation of the technology to local conditions in Brazil and also mass, thus having compact shape or regular and irregular eyes (Narimatsu et al., 2003). Alongside, Prato cheese mass is semi-solid, obtained by the coagulation of the milk in the action of the rennet of bovine origin followed by the pressing process for the elimination of whey; its maturation is relatively short, from 45 to 60 days, at the end of which it is presented with a parallelepiped shape with a smooth and well-formed surface (Gutierrez et al., 2004). The Brazilian cheese market grew in volume 9.4% per year in the period from 2006 to 2013, while the projection for the following 4 years was 11.4% per year on average, highlighting the consumption of ‘conventional’ cheeses such as mozzarella, Prato cheese and “requeijão” (cottage), which represent 68.9% of the total cheese production and is the most consumed in Brazil (Colombo Pimentel, 2017; Nepomuceno et al., 2016).

The exopolysaccharides (EPS) are extracellular polymers of high molecular weight with ramifications of repeating units of sugars, units composed mainly of glucose, galactose and rhamnose in different proportions. The production of EPS is attributed to lactic acid bacteria (LAB), which are characterized by their conversion of a large proportion of their carbon source, fermentable sugars, to lactic acid and the ability to divert a small proportion of those fermentable towards the biosynthesis of EPS (Huertas, 2010; Patel et al., 2012). The EPS are produced by LAB as Streptococcus thermophilus, which have an important role in the food industry for its ability to acidify, preserving and developing organoleptic characteristics in fermented food; different studies carried out show the stress their thickening, gelling, stabilizing and encapsulating properties, that directly influence the physicochemical, nutritional and sensory features of processed food, that includes dairy products (Aslim et al., 2005; Ayala-Hernández et al., 2008; Ayyash et al., 2018; Boza and Moreno, 2010; Dabour et al., 2005; Nepomuceno et al., 2016). The EPS produced by lactic acid bacteria can be bound to the cell in the form of capsules, be segregated as free materials or be in both forms simultaneously; in any case, no study confirms the exclusive production of the capsular type (Hassan et al., 2007; Zeidan et al., 2017).

The production of exopolysaccharides by lactic acid bacteria is highly variable in terms of quantity, chemical composition, molecular size, charge, chain and molecular rigidity. Nevertheless, investigations on the EPS referred its stabilizing action, decrease syneresis of products and generating texture, increasing the viscosity of the final product and interacting with other constituents of milk as the proteins and the micelles (Duboc and Mollet, 2001; Han et al., 2016; Ismail and Nampoothiri, 2014).

The biosynthesis of the EPS is complex, including various enzymes related not only to the polymer synthesis but also to the formation of the cell wall. The biosynthetic pathway can be divided into four sequences of reactions: reactions involved with the transport of sugar to the cytoplasm, the synthesis of the sugar-phosphate backbone, activation and attachment of sugars and the processes involved in the secretion of the EPS (De Vuyst et al., 2001).

Zisu and Shah (2003), in his study on the effect of pH and temperature on the production of exopolysaccharides by S. thermophilus, determined that the production of EPS, cellular increase, lactose metabolism and lactic acid production was influenced by the pH of the medium and the incubation temperature.

Moreover, EPS production by lactic acid bacteria has been studied in various dairy foods fermented to determine their characteristics and beneficial modifications, having cheese as one of the products of major interest in research as it constitutes an optimal setting for their development.

The diversity of heteropolysaccharides produced from lactic acid bacteria is related to the composition, structure, molecular mass and functionality of various fermented dairy products. The formation of the polymer depends on the conditions of the culture; in addition, EPS may have an impact on the stability, viscosity and development of beneficial properties in health (Dilna et al., 2015); specifically in the cheese, the production of EPS is important since it generates unique properties of texture, flavor, water retention and viscosity by the interactions of the EPS with the milk proteins, which are determined visually through the use of an electron microscope to observe that molecules of EPS not only interacted with caseins but also with whey proteins (Boza and Moreno, 2010).

The aim of this study was to evaluate the effect on the physicochemical characteristics of Prato type cheeses with the production of EPS by Streptococcus thermophilus and to compare the results obtained with traditionally-manufactured cheese.

Materials And Methods

The elaboration and analysis of the Prato cheeses were carried out in the dairy company FUNARBE and in the laboratories of the Department of Food Technology of the Federal University of Viçosa (Brazil).

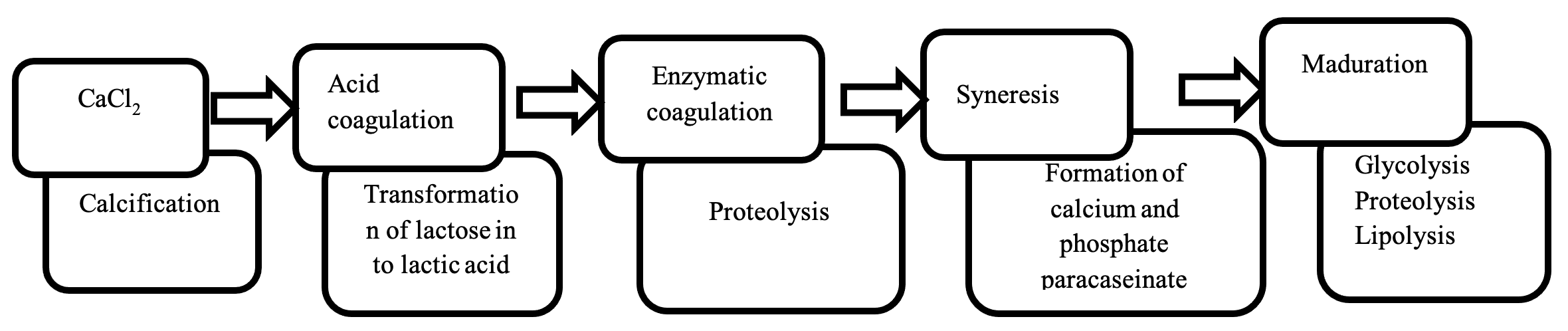

The elaboration of Prato cheese was held according to the subdivided block scheme with three different formulations: traditional treatment (T) = lactic culture with 80% of mesophiles (Lactococcus lactis and Lactococcus cremoris) and 20% Streptococcus thermophilus; lyophilized treatment (L) = lyophilized culture with 100% Streptococcus thermophilus; and replicated treatment (R) = replicated culture of Streptococcus thermophilus; the other manufacturing conditions were kept constant, in such a way that the biochemical processes of the elaboration and maturation stage will be generated as shown in Fig. 1; furthermore, the milk used for the three treatments derives from the same batch with an average acidity of 17°D and a fat content of 3.5%. The physicochemical characteristics of the cheeses were analyzed in triplicate during four stages of maturation (5, 25, 45 and 65 days after manufacture).

To evaluate the effect of the EPS synthesized by Streptococcus thermophilus, an experimental design was developed consisting of the interpretation of the results obtained through an analysis of variance with a 5% significance, in which the assumption of the existence of substantial differences between some of the mediums of the treatments (T, L, R) (H1) was contrasted considering the opposite case (H0); each pair of mediums was compared using the Tukey test at a 5% significance level.

Physicochemical analysis: The quality of milk and whey obtained during manufacture was determined by means of pH analysis, using a potentiometer; fat, by the Gerber method; total acidity, by titration (Ministério da Agricultura, 2017); and density, by densitometry thermometer. The microbiological quality of the milk was established by the standard plate count.

During the ripening of Prato cheese, various parameters were evaluated to compare the yield and physicochemical characteristics of cheeses prepared in the different treatments (T, L and R). The analyses performed in cheese within 5 days of manufacturing were: sodium chloride, through the methodology (Ministério da Agricultura, 2017); aqueous activity (aw), making use of the CX2T-Decagon Devices model meter (USA); total fat, by the Gerber method; fat in dry matter (FDM) and percentage of humidity, according to standardized method. The analyses performed at 25, 45 and 65 days of ripening were: pH, implementing a potentiometer; total protein, by the Kjeldahl method; soluble nitrogen at pH 4.6, by precipitation of the caseins with the addition of hydrochloric acid and non-protein nitrogen (nitrogen soluble in TCA 12%) according to the methodology (Martins, 2006).

Results And Discussion

The physical-chemical and microbiological characteristics evaluated in the milk used in the manufacture of Prato type cheeses had a density of 1.030 g/mL at 15°C, percentage of fat standardized at 3.5% with addition of skimmed milk, acidity of 17°D, percentage of total dry matter of 10.18 and 2.5*105 CFU/mL; all values were within the ranges established by the Brazilian legislation (Ministério da Agricultura, 2017); besides, the results of density and dry matter allowed the identification of the physicochemical and microbiological quality of the milk and the absence of alterations by the addition of water.

Table 1 presents the mean and the standard deviation of the physicochemical analyses carried out in triplicate five days after the production of the Prato cheese. The percentages of Fat in Dry Matter (FDM), statistically, did not present significant differences between the means of the three treatments (p>0.05). The cheeses of the treatments (T) and (R) were classified as fatty, for presenting values between 45% and 59.9%, while those of the treatment (L) as extra fat (>60%) (Ministério da Agricultura, 2017). The retention of fat when implementing the freeze-dried culture presumably occurred due to the action of Streptococcus thermophilus and its production of EPS, which form bonds with milk proteins and bacteria, preventing the exit of the fat globules of cheese, as reported in a Mexican research (Jiménez-Guzmán et al., 2009).

The percentages of fat in the Prato cheeses made with the three treatments (traditional, lyophilized and replicated) did not show statistically significant differences (p> 0.05); however, all the results exhibit higher values than the average fat percentage of the traditional Prato cheese, which is 45% (Ministério da Agricultura, 2017).

The percentage of humidity of the cheeses made with the freeze-dried treatment was greater with respect to the other treatments, presenting statistically significant differences between the means(p< 0.05). The Prato cheeses made by treatments (T) and (R) were classified as cheeses of medium humidity or of semi-hard consistency, with values in the range of 36% to 49%, on the other hand, the ones manufactured with treatment (L) were classified as having a very high humidity or a soft consistency, since they have humidity values above 55% according to the Brazilian legislation (Ministério da Agricultura, 2017).

The results of moisture and fat in the dry matter suggest a higher retention due to EPS production, although this retention only occurred in the cheeses manufactured with the culture of Streptococcus thermophilus in the lyophilized form.

The best economic yield result was found in the treatment (L) with a value of 7.9 L/kg, versus 8.03 L/kg and 8.88 L/kg for the treatments (R) and (T), respectively. The results are attributed directly to the amount of water in the dough and the low tendency to syneresis in treatments (L) and (R) which verify the formation of bonds between the EPS, the protein matrix of the cheese, the microorganisms and the fat globules observed by Jiménez-Guzmán et al. (2009). The water activity and the percentage of salt did not show significant differences (p>0.05) between the three treatments; despite this, higher values of aqueous activity and lower salt values were obtained in the replicated treatment. The aw has an inversely proportional relationship with the amount of salt in the cheeses because, when increasing the concentration of solutes in the aqueous phase, there is a decrease in its water activity. In the stage of salting the cheeses, the aw decreased by cause of the interactions that occurred between the free water and the sodium chloride in the brine; the osmotic exchange that took place in this stage was higher for the pieces of smaller cheeses, which were caused by the pressing stage, that, despite the implementation of molds of equal size and equal time in the brine (7 h), prompted the variation of the size of each one of the cheeses.

Table 2 introduces the average results of pH, Total Protein (TP%), Soluble Nitrogen (SN) in pH 4.6% and in TCA 12% during the 5, 25, 45 and 65 days of maturation of Prato cheeses for traditional (T), lyophilized (L) and replicated (R) treatments. This way, the most critical component is protein since it is the main responsible for the elasticity, texture and formation of compounds that characterize the flavor and aroma of the cheese during the process of proteolysis. On top of that, the results quantify the degradation of the proteins in extension and depth during ripening.

The pH behavior for the three treatments showed significant differences between the means (p< 0.05) in each stage of maturity evaluated, finding only a similar pH between the treatments (T) and (L) at 25 days of maturation. The proteolysis process is favored as the pH of the medium acidifies; in all three treatments, the behavior of the pH was descendant during 45 days of maturation due to the presence of lactose in the mass and its degradation to lactic acid by the action of Streptococcus thermophilus; subsequently, the pH increased as a result of the development of this starter culture and the low production of acid, as suggested by Aslim et al. (2005).

The values of total protein (TP%) for each treatment on different days did not show statistically significant at a 5% significance level; the components of milk preserved in the mass of cheese do not suffer losses but transformations during the ripening process.

Maturation rates expressed in terms of pH 4.6 soluble nitrogen (%) did not show significant differences (p>0.05) between averages of all treatments in 5, 45 and 65 days; notwithstanding, traditional Prato cheese with 25 days of maturation revealed significant differences (p< 0.05) in connection with all other treatments. Cheeses made with treatments (L) and (R) deployed more ripeness index 25 days after manufacture, indicating that the enzyme activity of coagulant and the enzymes from Streptococcus thermophilus were higher in those treatments; behavior that, occurs in most renin-coagulated cheeses, given that there is an initial fragmentation of casein in large peptides known as primary proteolysis, generated mainly by the action of the enzyme and by a lower contribution of the starter culture in the initial hydrolysis of intact casein, particularly β-casein; in fact, the quantification of this process represents the extension of maturation (Martins, 2006).

The depth of maturation, calculated in terms of SN TCA 12%, indicated a higher value for freeze-dried treatment at times 5, 25 and 45; yet, statistically, only the differences between the means (p< 0.05) at 65 days of maturation were significant, with the traditional treatment as the one with lower value in comparison to the other two treatments. The results convey that the degradation capacity of the peptide enzymes from the Streptococcus thermophilus contributed to the acceleration of the proteolytic process, creating compounds responsible for generating flavor, aroma and texture, typical of the cheese in less time for the treatments (L) and (R) because the major contribution of the starter culture in the degradation process is secondary proteolysis, which allows the hydrolysis of primary peptides in minor peptides and amino acids (Martins, 2001).

| Treatment | |||

|---|---|---|---|

| Analysis | Traditional | Lyophilized | Replicated |

| Fat in Dry Matter (FDM) | |||

| Fat (%) | |||

| Humidity (%) | |||

| Salt (%) | |||

| a,b: The values marked with the same letter indicate that statistically there are no significant differences between their means at 5% of significance | |||

| Analysis | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pH | TP (%) | SN pH 4,6 (%) | SN TCA 12% (%) | |||||||||

| Time | T | L | R | T | L | R | T | L | R | T | L | R |

| 5 | ||||||||||||

| 25 | ||||||||||||

| 45 | ||||||||||||

| 65 | ||||||||||||

| a,b,c: The values marked with the same letter indicate that statistically there are no significant differences between their means at 5% of significance | ||||||||||||

Conclusion

The production of exopolysaccharides by cultures of Streptococcus thermophilus influenced positively in the physicochemical characteristics of Prato cheeses made with treatments (L) and (R) with respect to the traditional treatment, improving retention moisture and accelerating the process of proteolysis in the maturation index for 25 days for treatment (T) and 65 days of manufacturing in depth for the treatment (R), aspects that may allow the development of characteristics such as texture and flavor.

Acknowledgement

To the Federal University of Viçosa (Brazil) and the University of Caldas for their contribution to the development of this research; special thanks to Professor José Antonio Márquez for his guidance and direction; to Fernanda Firmino, Bet"a" ̂nia Amorin and other laboratory staff for their valuable collaboration.

Author Details

1Dairy Science and Technology, Universidade Federal de Viçosa, UFV Campus, 36570-900 Viçosa, MG Brasil

2Department of Engineering, Universidad de Caldas, 65 St N. 26-10,

3Research Institute in Microbiology and Agroindustrial Biotechnology, Universidad Católica de Manizales, Road 23 N. 60, Manizales, Colombia

References

Rights and permissions

Open Access: This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third-party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

Cite this Article

DOI: http://doi.org/10.19026/ajfst.17.5984

Authors

- Paola M. Alzate Montoya

- José A. Marques Pereira

- Mario H. Marín Marín

- Katherin Castro-Ríos