Advance Journal of Food Science and Technology

A Quick Biochemical Comparison between the Traditional Fermentation of Plantain Wine and Banana Wine Produced in Republic of Congo

Advance Journal of Food Science and Technology 2020 18: 15-21

Cite This ArticleAbstract

The aim of this study is to quickly assess the physicochemical parameters of plantain wine and to be acquainted about the microorganisms genera involved in the fermentation. Numbers of fermented beverage are locally produced in several areas of the Republic of Congo by using local materials. The plantain seems to be a fruit of choice in the manufacture of fermented baverage. This study allow to improve the fermentation carried out in a traditional way with pH values around 4.5±0.4. In addition we showed that plantain wine contain more sugar that desert banana by allowing to obtain 16° of alcohol from plantain and 9° from dessert Banana. Finally the plantain wine contain a couple of Mineral composition including Ca, Fe, Cu, K, F and PO3. This wine showed a very interresting profile in terms of beverage preservation.

Keywords:

Introduction

In the Republic of the Congo, there is a wide variety of traditional fermented drinks, including sugar cane wine ("loungouila"), palm wine ("nsamba"), honey wine ("duma") and local wines basing on banana, orange, pineapple and grapefruit are not yet documented. The plantain wine commonly known as "banana wine" is called as "Mbamvu" in some localities of Republic of Congo like the Departement of Bouenza (Kayath et al., 2016). This fermented local baverage is produced according to long and complex traditional methods. The rather crude fermentation technique consists in letting the juice extracted from the fruit turn to produce alcohol. Spontaneous fermentation is achieved by the presence of microorganisms from the plant material Physicochemical parameters are generally poorly controlled (Kayath et al., 2016).

Also known as "Urwagwa" in Rwanda, banana wine is mainly consumed in three quarters of the Rwandan territory where banana cultivation is a major agricultural activity (Kanyana et al., 2013). Traditional practices show that Mbamvu is prepared from mature plantain slices suspended in water for (1) to (3) weeks. The microorganisms responsible for alcoholic fermentation are usually present on the surface of the raw materials that serve as their substrate (Juturu and Wu, 2016). In addition, the hygienic quality is based on the transformation conditions and the material used (Abriouel et al., 2007).

The choice of the fruit is justified by the fact that the plantain is the most consumed fresh fruit in the world (Singh et al., 2016) but baverage produced from plantains is little known.

So far, the techniques of making plantain wine is poorly controlled and pose many difficulties from the hygienic point of view, rate of fermentation, alcohol, taste variation, which can lead to different health problems.

Few studies from the microbiological analysis and physicochemical parameters have been carried out To this end, in order to valorize that banana wine and make more comparisons with dessert banana somes issues could be assessed. This will be for cused in the process of plantain wine manufacture, the influence the physicochemical parameters and microbiological quality.

Materials And Methods

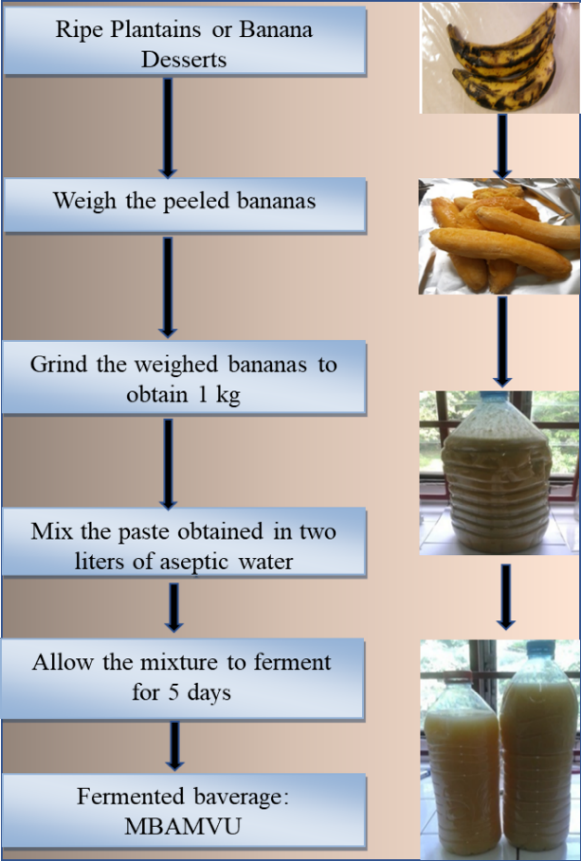

Manufacture of plantain wine and preliminary isolation of microorganisms: The biological material used in this study is the plantain and dessert banana. The wine had been made in the laboratory by improving the traditional process. The plantain has been bought at the market of Brazzaville (Mpila Market) coming from different origins such as Department of Plateaux (Djambala) and Departement of Bouenza (Republic of Congo). Plantains are used until the skin becomes black and then weighted first of all, then crushed and mixed with water. The fermentation has been followed in 4 to 5 days and then the ferment is the plantain wine.

Dilutions were done and bacterial suspension was streaked on PCA, Malt agar, MRS, LB, Chapman, SS and TSN media as discribed by the manufacturers. Petri dishes were incubated at 37°C for 24 h to 48 h. After the first isolation on Petri dishes, different colonies were obtained. Each colony from MRS of different appearance was separately isolated. Purification of the isolates was rigorously done by successive and alternating subcultures. Purity was estimated by using a microscope for morphological characterization. Gram status was determined by using 3% KOH.

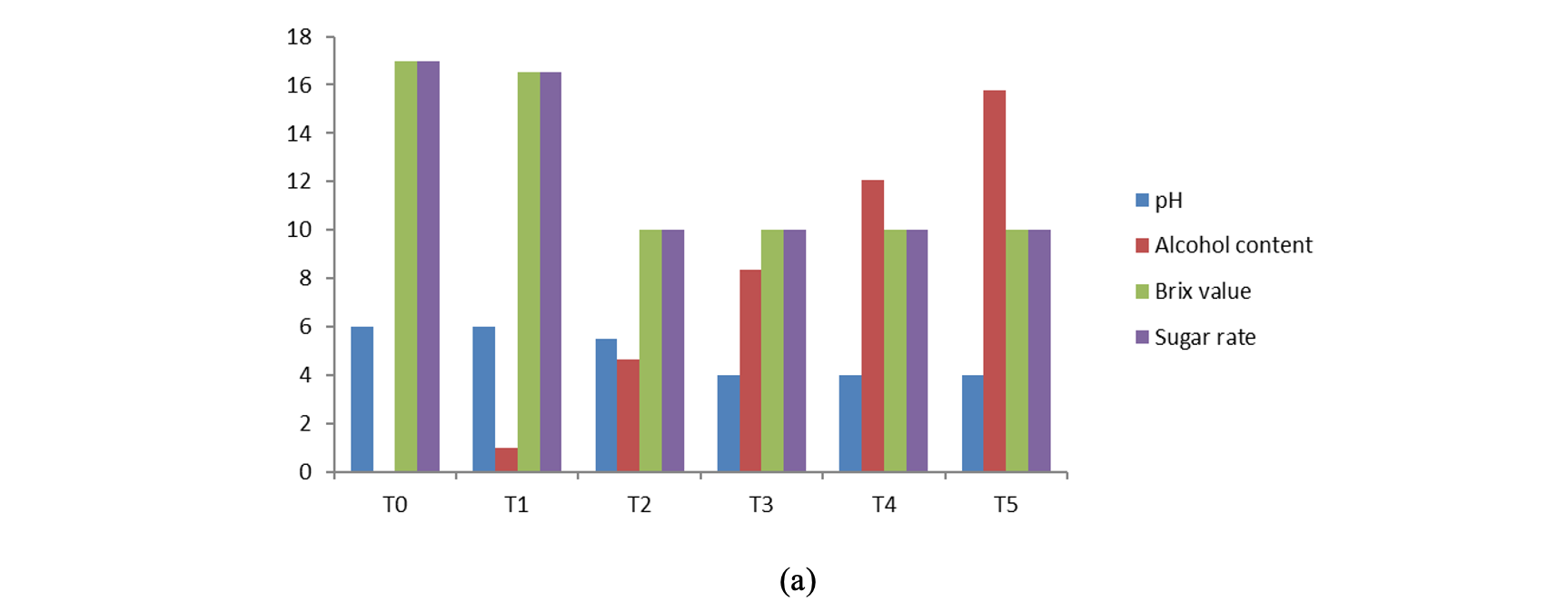

Measurement of temperature, pH, sugar rate and alcohol degree: The ambient temperature has been measured in all stages of fermentation. The pH was measured before, during and at the end of the fermentation using a pH meter. The measurements were carried out on 10 mL of the suspension to be tested at T0 = 0h, T1 = 24 h, T2 = 48 h, T3 = 72 h and T4 = 96 h. The total sugar content during the fermentation was determined by the Brix method using a refractometer (HANNA instruments HI9680, Belgium-Luxembourg). At different times (T0, T1 = 24 h, T2 = 48 h, T3 = 72 h and T4 = 96 h), 1 mL of the fermented product was transferred to the Eppendorf tube and centrifuged at 3000 rpm for 10 min. The Brix degree of each solution is measured by depositing a drop of the supernatant of the sample to be tested on the refractometer lens. The alcohol content of plantain wine was determined in two ways either using the appropriate procedures of Wood (Woo et al., 2010) or from the value of the average sugar concentration in the juice. The distillation was done on an initial volume of 3 L. Briefly, 1 L of banana wine was transferred to a flask. After homogenization of the plantain wine, the distillation was carried out at a temperature of 80°C. The distillate was collected at the outlet of the refrigerant. Thus, 20 mL of distillate was collected at each distillation tower. The densimeter was used to determine the alcohol content.

Plantain wine mineral content: The concentrations of the following minerals: iron, calcium, fluorine, magnesium, silicon, aluminum, chlorine, chromium, copper, potassium, phosphate, sulphite ion, sulphate ion, zinc were calculated at the end of the fermentation according to the manufacturer's procedure. Briefly, a 10 mL solution of Mbamvu was sampled in order to test the presence or absence of mineral elements at a wavelength of 520 nm. This solution was closed and placed in the measuring chamber. The pellets containing the mineral elements were added for quantification as a function of each mineral element.

Results

The process of making plantain wine: At the beginning of this study, we sought to improve the process of making plantain wine usually made in 2 to 3 weeks in the Department of Bouenza. The following diagram shows that plantain wine can be made in just 5 days and obtain a wine that has the organoletic characteristics such as color close to the palm wine. The feelings of this baverage seem to be less aggressive and finer because of its bioactive compounds. The dessert banana wine was also made according to the same diagram (Fig. 1).

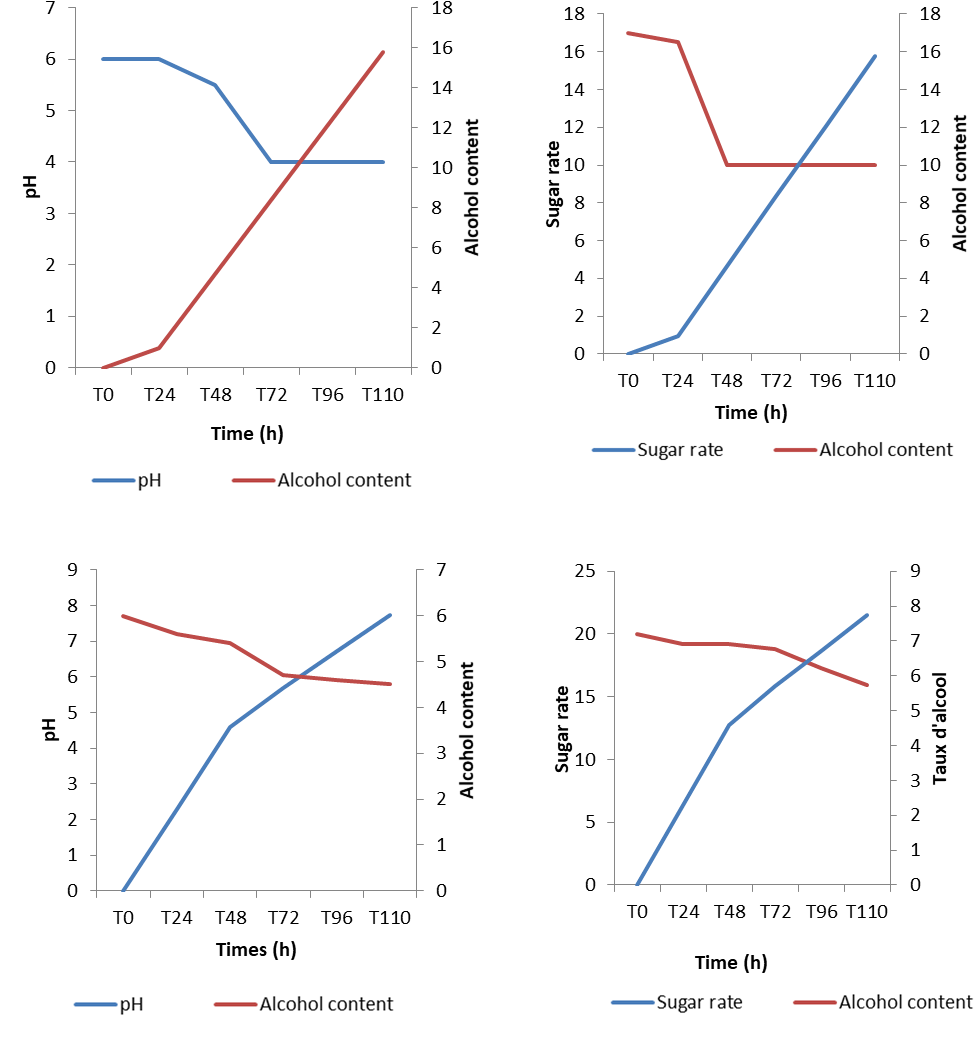

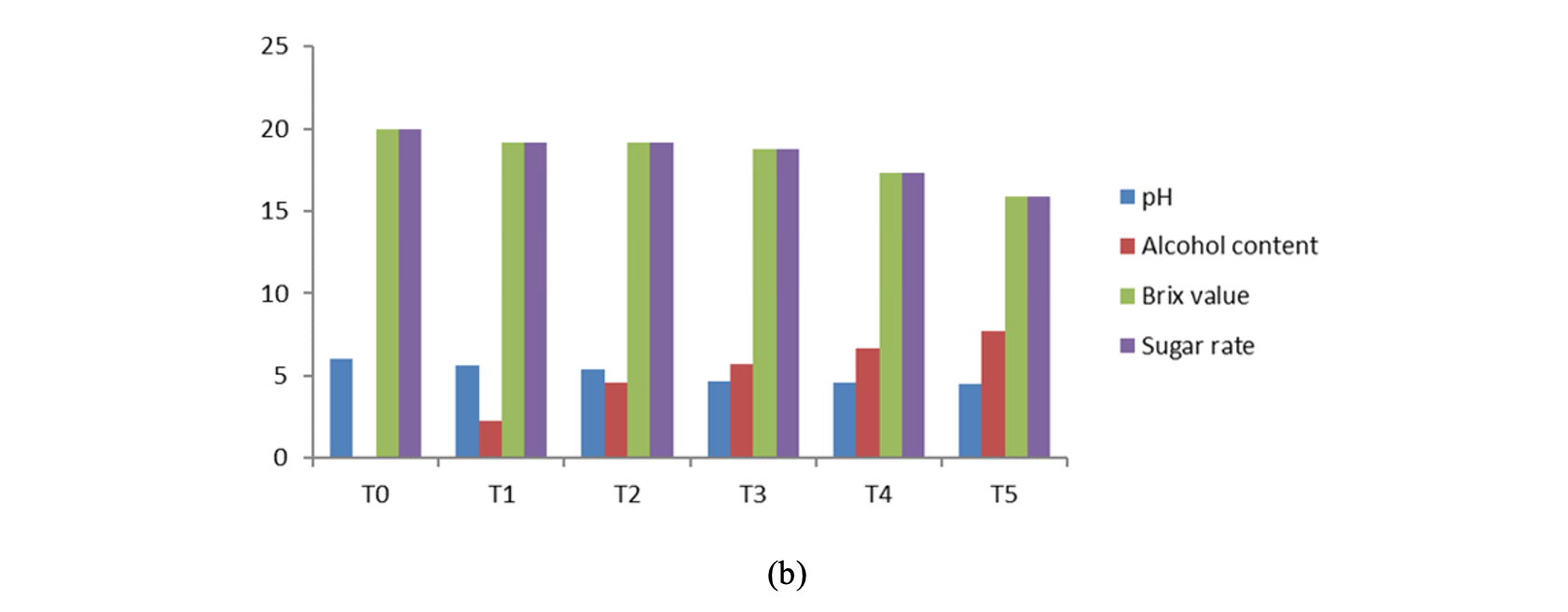

Evolution of pH, sugar and alcohol levels during plantain fermentation: In order to understand the background of metabolites during the fermentation of plantain wine, samples were taken before, during and after fermentation, by comparing plantain and dessert banana coming from different areas. The pH values, total sugars of the plantain Collected in Brazzaville and coming from the departement of Pleateaux and departement of Bouenza, after the advanced ripening stage, were taken at each stage of the fermentation.

Figure 2 shows that the pH decreases fastly after the first day of fermentation from 6 to 4.4 representing an acidic pH. This was stabilized at pH 4,2 on the fifth day of fermentation, while the alcohol level increases to 16° at the end of the fermentation. The evolution of the sugar and alcohol levels are shown in Fig. 1. It shows a decrease in sugar level concomitant with the increase in the level of alcohol in the medium during the fermentation. At the end of the experiment the values of the sugar level are respectively around 10 g/L (Fig. 2 up).

At the same time, we have sought to understand variations in physicochemical parameters by working on plantains coming from departement of Plateaux (Djambala). In this case, although the variation of the pH behaves in the same way as in the case of the plantains from Departement of Bouenza, we note that the alcohol content was about 8°. This also showed that the decrease in the sugar level is concomitant with the increase of the alcohol content in the medium. At the end of the experiment the values of the sugar level are around 15.1 g/L (Fig. 2).

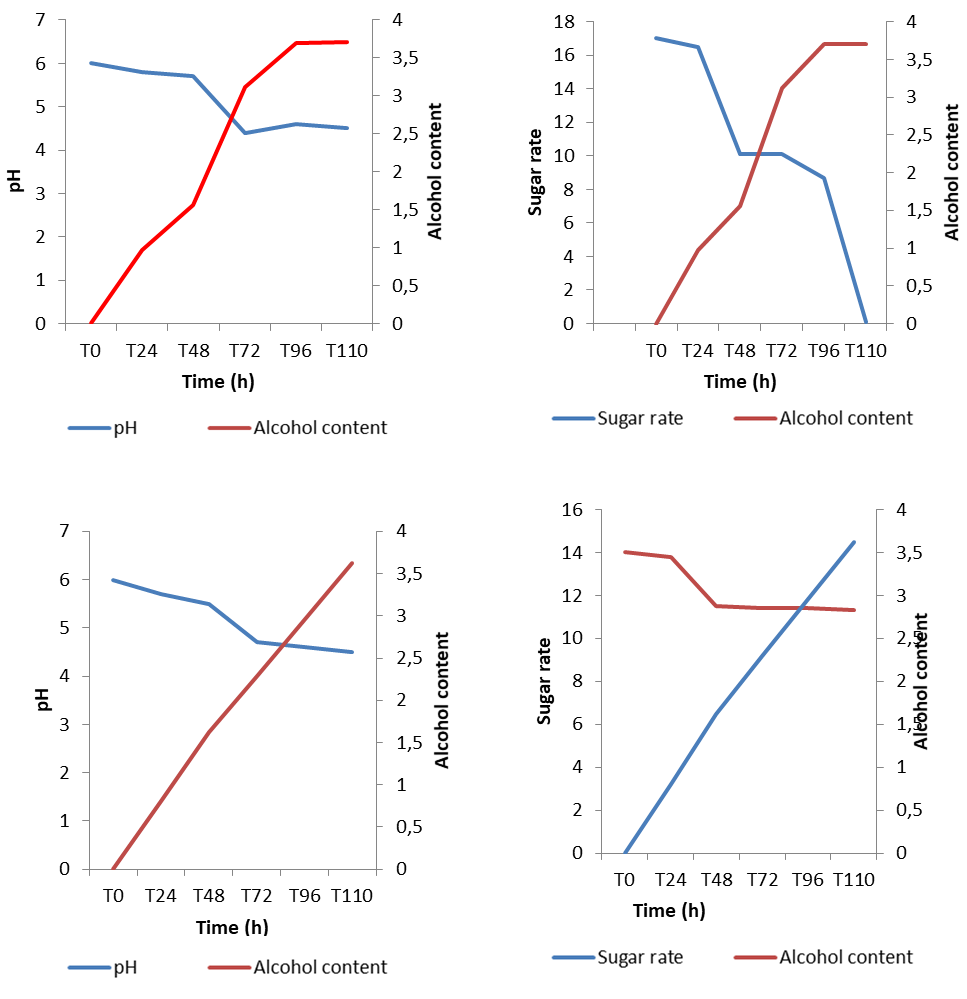

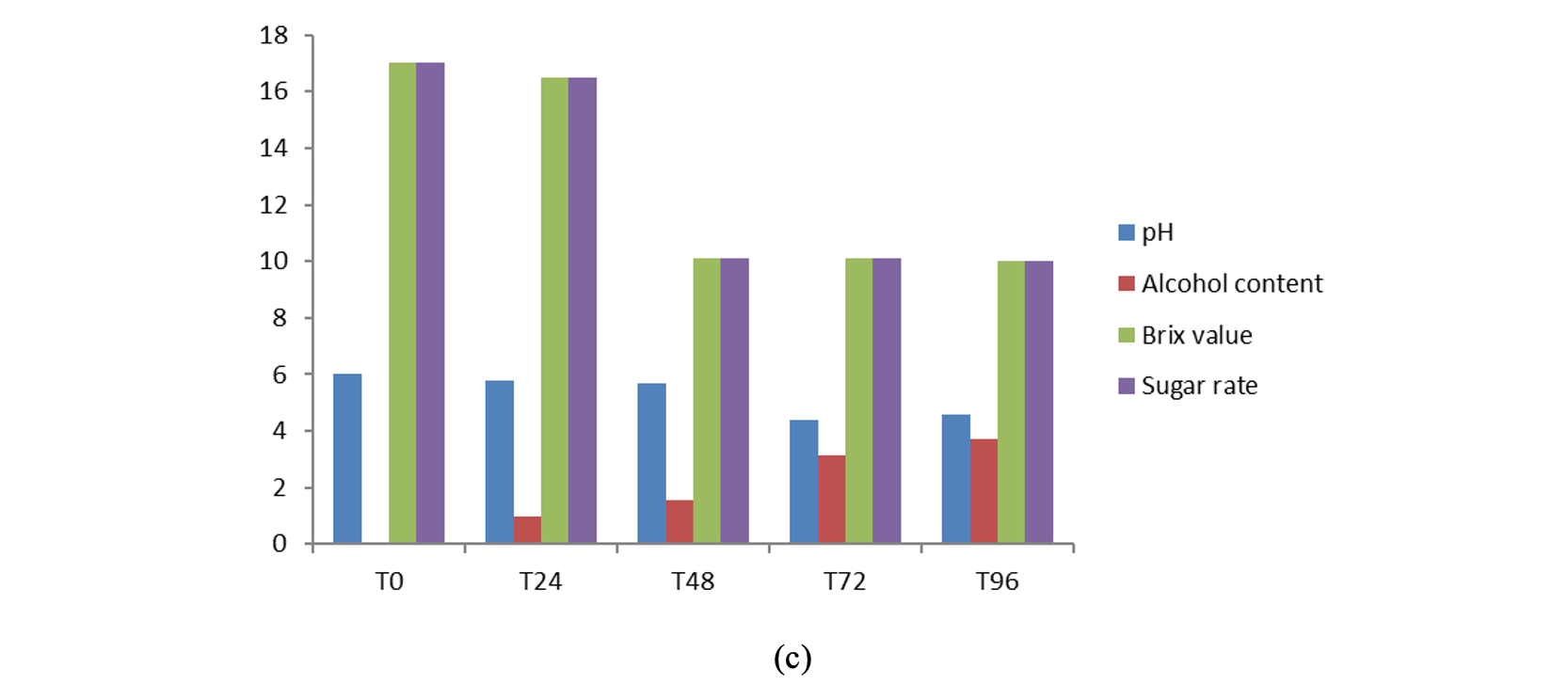

Comparison during fermentation of banana dessert: Comparisons on the evolution of the rate of physicochemical parameters were also made on the dessert banana. Also in this case, the average pH values of the total sugars determined after the advanced ripening stage were taken at each stage of the fermentation. Figure 2 shows that the pH decreases from 6 to 4.5 while the alcohol level increases to 3.7° at the end of the experiment. There is a decrease in the concomitant sugar level with the increase in the level of alcohol in the medium. The values of the sugar level are almost zero and the alcohol level does not change. The same result was obtained with dessert banana from Brazzaville (Fig. 3 Up) and those one from Departement of Plateaux (Fig. 3).

Mineral composition of plantain baverage: We assessed the mineral composition of plantain wine and we found that this wine contains Ca, Fe, Cu, K, F and PO3. Other elements were obtained in the form of traces such as Mg, Mn, Al, SO3, SO4 and Zn. The mineral analysis of plantain wine showed that the presence of Cl (5.9 mg/mL) and Cr (1.3 mg/mL) at the end of the fermentation of which the content (Table 1).

Preliminary microbiological characteristics of plantain wine: The results in Table 2 showed that aerobic mesophilic microorganisms increase during the fermentation process using PCA medium. The measured temperatures were around 28 and 32°C. Cultures on TSN and EMB media showed that plantain wine does not contain Clostridium spp. nor any enterobacteria that can be cultivated under the conditions tested.

In addition, tests using SS media, Cetrimide, Chapman showed the absence of bacteria of the genus Salmonella spp., Shigella spp. And Pseudomonas aeruginosa and Staphylococcus aureus. The MRS, Mossel and Malt agar media allowed the prime identification of isolates oriented to the genera of Lactobacillus, Bacillus and yeast isolates as well, although Lactobacillus appear from the second day of fermentation (Table 2).

| Vin de Banane (Mbamvu) | ||||||

|---|---|---|---|---|---|---|

| Ca | Fe | F | Mg | Si | Al | Cl |

| 50 | 1,16 | Very rich | Little trace | Little trace | Little trace | 5,9 |

| Cr | Cu | K | PO3 | SO3 | SO4 | Zn |

| 1,31 | 0,8 | 4,1 | 0,28 | Little trace | Little trace | Little trace |

| Culture media | T0 (ufc/mL) | T24 (ufc/mL) | T48 (ufc/mL) | T72 (ufc/mL) |

|---|---|---|---|---|

| PCA | 2.2.105 | 6.6.106 | 1.1.107 | ND |

| LB | 3.6.105 | 2.7.105 | 1.7.105 | ND |

| MRS | ND | 5.7.105 | ND | ND |

| Malt Agar | 2.8.105 | 1,16.104 | 1.55.105 | 1.36.106 |

| Mossel | 2.1.103 | 2.2 104 | 3.105 | 4.106 |

| TSN | 0 | 0 | 0 | 0 |

| EMB | 0 | 0 | 0 | 0 |

| SS | 0 | 0 | 0 | 0 |

| Chapman | 0 | 0 | 0 | 0 |

| T0 = First day of fermentation, T24 = One day of fermentation, T48 = Two days of fermentation, T72: Three days of fermentation | ||||

Discussion

In this study the main goal was to appreciate and to improve fitst of all the fermentation process that is usually done between two to three weeks in the areas the Department of Bouenza, Ouesso in the Department of Sangha (Republic of Congo). We considered trying to compare the fermentation of plantain and banana (Chabi et al., 2018; Pereira and Maraschin, 2015). We first of all set the process of plantain wine. The plantains well walled, crushed and mixed with water, ferment between 3 to 5 days, producing a slightly aggressive baverage with a pleasant taste. It should be noted that in East Africa, the fermentation takes place in the presses and lasts 1 day to 3 days depending on whether it is done in a ditch or the ambient air, or depending on the degree of desired alcohol (Parawira et al., 2012; Woo et al., 2010).

In order to analyze the acidity of Mbamvu (plantain or dessert banana), pH values were taken before and at the end of the fermentation where they are about 4.5±0.4 representing an acidic pH. Fermented of potopoto (a Congolese fermented maize product), palm wine are also acidic (Abriouel et al., 2006; Abriouel et al., 2007). The fermentation of peanaple juice (Nguyen et al., 2019) and star fruit juice fermentation are also acidic (Lu et al., 2018). At this pH, there are larger microorganism populations especially represented by Lactobacillus spp, Bacillus spp and yeast that can easily grow (Ouoba et al., 2010; Abriouel et al., 2006; Abriouel et al., 2007). Mecanisms of acidic resistance L. plantarum and yeast have been documented (Zhao et al., 2019; Godinho et al., 2017). Henick-Kling et al. (1989) demonstrated that throughout the development of wine, the pH acts on several levels: it participates in the selection of species according to their acid-resistance, it directs their metabolism and determines their speed especially of multiplication as evidenced by our results obtained on PCA culture medium (Henick-Kling et al., 1989). This result was also observed in previous work in Rwanda showing the same values of pH as we obtained in this study (Habimana et al., 2017).

Although banana fermentation has been studied in Rwanda, few studies have been reported on physicochemical characterization. Alcohol content is one of the factors that affects the quality of banana wine and can also be used to indicate the degree of fermentation throughout the fermentation process (Woo et al., 2010). During fermentation, the starch is converted to glucose by enzymes such as amylase. The glucose is then transformed by the yeast to give alcohol and CO2 (Shen et al., 2004; Martinez-Garcia et al., 2017). Temperature conditions also contribute very strongly to the alcohol content of wines (Jung et al., 2016; Mastanjevic et al., 2017), since the traditionnal fermentation process is conducted at unstabilized and uncontrolled ambient temperature (Parawira et al., 2012), temperature must be controled. We show in this study the temperature is between 28 and 32°C. This temperature could help to more optimize fermentation.

By controling the temperature of mbamvu fermentaion we have shown that the degree of alcohol of the plantain depends on the origin of the banana. We note that the Brazzaville bananas from the Bouenza department could reach up to 16° (Fig. 4a) whereas the Djambala bananas were around 8° (Fig. 4b). Comparing with the dessert banana, the values are low and around 4°. This difference is observed because plantain is sweeter than dessert banana (Singh et al., 2016). Which explains the high rate of alcohol (Fig. 4).

The mineralogical composition of banana wine consists mainly of phosphorus, sodium, potassium, calcium, magnesium, iron, copper, zinc and manganese (Forster et al., 2003). By checking the composition of the Mbamvu wine, we noted the presence of Ca, Fe, K, F, Cu, PO3 Cr and trace elements such as Mg, Si, Al, Cl. It is important to notify that Cl and Cr are not part of the chemical composition of banana (Forster et al., 2003). These two chemical elements could come from the equipment used or the previously distilled tap water.

Conclusion

This study allowed to improve the fermentation process of the plantain wine by characterizing from a physicochemical and a quick microbiological assessment. We also noted that plantain contained more sugar that dessert banana. This is lead to obtain 16° and 8° from plantain and dessert banana. Quick genera have isolated including Bacillus spp., Lactobacillus spp and yeast. This is a very start point for microorganisms. Molecular identification by using 16S rRNA gene and PCR multiplex is on the way of the next work. The processes and methods we used, could serve as a basis and example for the manufacture of all other local wine sunder better conditions and standards for the health of the population. The control of local beverages production could be the very important input of nutritious beverages for the benefit of the people because contains very important bioactive compounds.

Data availability: The Excel sheet including the data used to support the findings of this study is available from the corresponding author upon request.

Conflict Of Interest

The authors declare that the research was conducted in the absence of anyintellectual commercial or financial relationships that could be construed as potential conflicts of interest.

Acknowledgement

We are grateful to Prof. Clobite Bouka Biona (Université Marien NGOUABI), Dr. Bienvenu Dinga (Université Marien NGOUABI), Prof Anne Botteaux and Ms Dalila Lakhloufi (Laboratory of Molecular Bacteriology, Faculty of Medicine, Free University of Brussels, Brussels, Belgium) for their continuous encouragements and material support. This study was supported in part by Institut National de Recherche en Sciences Exactes et Naturelles (IRSEN).

Author Details

1Laboratoire de Biologie Cellulaire et Moléculaire (BCM), Faculté des Sciences et Techniques, Université Marien N’GOUABI, BP. 69, Brazzaville, République du Congo

2Institut National de Recherche en Sciences Exactes et Naturelles (IRSEN), Avenue de l’Auberge Gascogne, B.P 2400, Congo, Brazzaville

3Ecole Normale Superieure (ENS), Université Marien N’GOUABI, BP. 69, Brazzaville, République du Congo

References

Rights and permissions

Open Access: This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third-party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

Cite this Article

DOI: http://doi.org/10.19026/ajfst.18.6042

Sections